Design

Globe Architectural & Metal is capable of providing help and guidance with interior elevator design as well as, material selection. We have built elevator interiors in countless shapes, sizes, and materials. If your project doesn’t have an architect, please consider letting our professionals help you make the right choices.

Engineering

Let Globe do all the heavy lifting when it comes to engineering your project. With years of experience, we are able to provide properly engineered products for every application. Our products are engineered to last and we stand behind what we build.

Manufacturing

Manufacturing is simply what we do. Globe Architectural & Metal has been in the manufacturing industry for more than 30 years and our products show it. Give us a chance to build your class A materials, and you’ll understand our longevity.

Shipping

When you care for your products as much as we do at Globe. Then you understand the importance of shipping and getting materials to the requested locations on time and without damage. We have our own in house shipping and crating department to ensure the quality of our delivery. Additionally, all our trucking services are sub-contacted threw verified reputable sources.

Installation

One thing we don’t do at Globe is install our products on-site. However, we do supply well designed interiors that make the installation process as easy as possible. Additionally, we provide step by step installation guilds to assist mechanics on site. The installation of our materials is something that we assist with every step of the way.

Project Concepts & Design

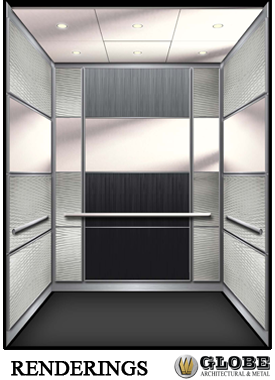

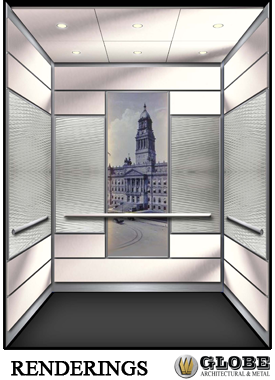

The Globe Architectural & Metal Professionals Have Extensive Experience In Elevator Design and Elevator Interior Architectural Concepts.

Start Your Project With Design Options –

Once the initial jobsite survey is complete, or rough cab dimensions are confirmed, we can begin to understand the elevator interior landscape. Different design options can be better implemented depending on the width, depth, and height of you cab interior.

Elevator cab interior landscape can often times dictate panel layout. Additionally, in some cases material sizes will also effect panel layout and design. This is why it’s very important to understand materials as well as, material application. At Globe Architectural & Metal, we are well suited to assist with the implementation of all requested materials.

Feel free to Contact us anytime, or review additional DESIGN CAPABILITIES by clicking the links.

Engineering Class A Materials

The engineers at Globe Architectural & Metal have years of experience in producing elevator products. We work with our customers to produce a well built product that meets all the needs of our customers both structurally and aesthetically.

Properly engineering elevator cab shells and interiors is a well thought out process. It takes experience, understanding, and craftsmanship to create quality materials that will last for years to come. Feel free to reach out to the professionals at Globe and see what our vast experience in engineering can do to provide your company additional confidence in the materials you install.

Drafting Projects From Start To Finish

Drawing details and elevations are created for every part that passes through our shop. These are detailed images that show the dimensions of any specific product being constructed. At Globe Architectural and Metal, full size prints are included with the product to aid in the installation process.

All drawings are finalized and included in submittals for approval. Final drawings must be reviewed and approved for products to move into the manufacturing phase of production.

The image to the right shows a cab exterior shell and interior suspended ceiling. The reflected ceiling plan is a part of our drawings used for manufacturing the top portion of the elevator cab.

Manufacturing Our Products

Manufacturing Success

From start to finish, all products made by Globe Architectural and Metal are fabricated and constructed entirely in-house. This allows the company to handle a wide range of elevator cab products. Mainly, Globe possesses the capabilities to create completely custom elevator cabs with any material on the market today. This is a process that requires masterful craftsmanship, knowledge, and experience to execute properly. Lucky for our customers, Globe has been doing this for over 30 years.

Manufacturing Capacities

All Metals .036″ – .025″

- Shear

- Bend

- Punch

- Weld

- Polish

- Lacquer

All Hardwood & Composites

- Cut

- Rout

- Finish

- Stain

- Paint

The Shipping Process

Shipping is something that is taken seriously at Globe Architectural and Metal. The goal of our shipping practice is to ensure our products are safely and securely packaged and arrive at the job site exactly as they left our facility. In order to accomplish this, we use a large majority of crates. As you can see in the crating process above, most crates are made of plywood. The box is then lined with hard polystyrene to help protect against movement and any shift in position within the crate. Furthermore, the product is also covered and protected with any necessary vinyl or soft foam. Lastly, all products are cleated down and securely covered.

Large Scale Shipments

For shipping entire cabs, banding is used to secure everything onto one skid. Shipping large skids allows Globe to send entire elevator cabs in one or two skids upon request. For jobsite delivery, Globe contracts exclusive use trucks, and direct couriers, to deliver directly from our dock to the job site. This eliminates any chance of damage during transit and provides a specific time window for delivery if necessary.

Shipping Multiple Cabs

All of the creating and skid packaging is done completely in-house. This process allows for a higher level of product security and stability when shipping elevator cab components. In the picture to the left, all of the skids are loaded per car for the project. By custom fabricating every crate, Globe is capable of maintaining orderly skid deliveries. This process is advantageous during the delivery, and installation of our product.

Seamless Installation

At Globe, we know well designed products make a difference when it comes to saving time on the job. This is why we continue to implement designs with the intention of making installation as easy as possible in the field. Additionally, All interiors manufactured by Globe are removable. This key component allows for efficient product replacement in the event damage occurs over time.

Every product delivered by Globe is ready for immediate installation. All wall panels are pre-fit to the shells and sub wall panels for every elevator interior supplied. Additionally, Globe Architectural and Metal takes the time to attach any necessary components such as clips, bolts, and angles for erecting a properly aligned custom elevator cab. Along with any required hardware, larger products include templates and spacers to aid with installation. Smaller products such as Destination Products and fixtures always include the required material as well.

To see installation examples please scroll down. The images included show how finished wall panels are pre-installed with clips so they can be placed onto aluminum sub-walls. This allows the panel to slide into place immediately after it is pulled out of the crate. Furthermore, the slotted sub-walls hold wall panel clips in the proper position, allowing minimal need for adjustment. These aluminum sub-walls are fastened to existing shell walls with hardware, as shown in the second picture down on the right. For any questions about the installation process of Globe Architectural and Metal products, please Contact us via email or by calling 262-250-1120.

We also can include an installation guide with the drawings.

Download an example of a previously supplied installation guild for reference – Installation Guild Example

Sub-walls and Wall Panels

To your left is an image that shows the aluminum sub-wall built to house four vertical wall panels and one lower horizontal panel.

The image on the right also shows a sub-wall made by Globe. As you can see, all of the slots are positioned so the wall panels can be easily mounted and aligned.

The image to the left shows wall panels being mounted in-house prior to crating. All wall panels are pre-fit and marked before shipping.

The image to the right shows how easy it is to fasten the sub-walls to the existing cab shell walls.

On the left you’ll see a wall panel being pre fit and aligned. If you look at the middle of the sub-wall you can see the marking that will correspond with that specific panel. Markings on the sub-wall can also be seen in both of the top two images. All wall panels and sub-walls are marked so there is no second guessing.

The photo to the right is displaying this particular elevator cab’s rear wall. In this case, once the flat screen is in place the wall panels are ready to be mounted to the sub-wall.

The image to the left shows the cab’s sub-walls in the field.

The image to the right is displaying the rear wall with its feature panel mounted over the flat screen. All wall panels on the rear wall of this cab are glass.

These two final pictures are images of both cabs after the wall panels are fit.

Globe Architectural & Metal

Your source for custom elevator cab interiors.

Custom Projects

Interior Design & Architecture by Globe Architectural & Metal

Copyright © 2023. All rights reserved.